Cov txheej txheem rau kev kho cua sov yog dab tsi?ncaj seam hlau yeeb nkab?

Ua ntej tshaj plaws, qhov kev tsim qauv ntawm cov pwm kev siv tshuab yuav tsum tsim nyog, qhov tuab yuav tsum tsis txhob sib txawv dhau, thiab cov duab yuav tsum sib npaug. Rau cov pwm uas muaj kev hloov pauv loj, cov cai hloov pauv yuav tsum tau nkag siab, thiab qhov kev tso cai ua haujlwm yuav tsum tau khaws cia. Rau cov pwm loj, zoo thiab tsis sib xws, qhov kev teeb tsa ua ke tuaj yeem xaiv tau. Rau qee cov pwm zoo thiab tsis sib xws, kev kho cua sov ua ntej, kev kho cua sov laus thiab kev kho cua sov nitriding thiab tempering tuaj yeem xaiv los tswj qhov tseeb ntawm cov pwm. Thaum kho qhov tsis zoo xws li qhov xuab zeb, qhov cua thiab kev hnav ntawm cov pwm, cov khoom siv kho nrog me me thermal cuam tshuam xws li lub tshuab vuam txias yuav tsum tau xaiv kom tsis txhob hloov pauv thaum kho.

Cov pwm me me thiab tsis sib xws yuav tsum tau kho ua ntej kom tshem tawm cov kev ntxhov siab seem thaum lub sijhawm ua haujlwm. Rau cov pwm me me thiab tsis sib xws, yuav tsum xaiv kev siv lub tshuab nqus tsev los tua cua sov thiab kev kho kom txias tob tom qab tua hluav taws kom deb li deb tau yog tias muaj xwm txheej tso cai. Ntawm lub hauv paus ntawm kev ua kom lub pwm tawv, yuav tsum xaiv kev txias ua ntej, kev txias theem lossis kev tua hluav taws sov kom deb li deb tau.

Xaiv cov khoom siv kom tsim nyog. Rau cov pwm me thiab tsis sib xws, cov hlau pwm me me uas muaj cov khoom siv raw zoo yuav tsum tau xaiv. Cov hlau pwm uas muaj kev sib cais carbide hnyav yuav tsum tau cam kom raug thiab raug kho cua sov quenching thiab tempering. Rau cov hlau pwm loj thiab tsis cam, kev kho cua sov ob zaug refining tuaj yeem ua tiav. Xaiv qhov kub thiab txias kom tsim nyog thiab tswj qhov ceev ntawm kev kub. Rau cov pwm me thiab tsis sib xws, kev kub qeeb, kev kub ua ntej thiab lwm txoj kev kub sib npaug tuaj yeem siv los txo qhov kev hloov pauv ntawm kev kho cua sov pwm.

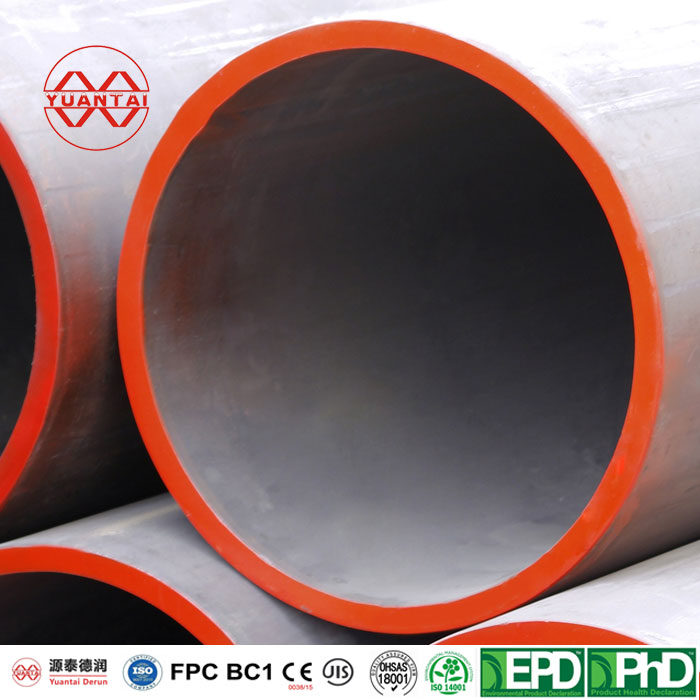

JCOE yog ib lub tshuab ua yeeb nkab rau kev tsim cov yeeb nkab hlau loj thiab tuab. Nws feem ntau siv cov txheej txheem tsim khoom ntawm kev vuam ob sab hauv qab. Cov khoom siv dhau los ntawm ntau yam txheej txheem xws li milling, pre bending, bending, seam closing, internal welding, external welding, straightening, thiab flat end. Cov txheej txheem tsim khoom tuaj yeem muab faib ua N + 1 kauj ruam (N yog tus lej zoo). Lub phaj hlau raug pub rau sab nraud thiab khoov raws li qhov loj me ntawm cov kauj ruam teeb tsa kom paub txog kev tswj hwm tus lej JCO tsim. Lub phaj hlau nkag mus rau hauv lub tshuab tsim kab rov tav, thiab nyob rau hauv kev thawb ntawm lub laub pub mis, thawj theem ntawm kev khoov ntau kauj ruam nrog N / 2 kauj ruam raug ua kom paub txog "J" tsim ntawm ib nrab pem hauv ntej ntawm lub phaj hlau; Hauv theem thib ob, thawj zaug, lub phaj hlau tsim los ntawm "J" yuav raug xa mus rau qhov chaw teev tseg hauv kev taw qhia transverse sai sai, thiab tom qab ntawd lub phaj hlau tsis tau tsim yuav raug khoov ntau kauj ruam ntawm N / 2 los ntawm qhov kawg kom paub txog kev tsim ntawm ib nrab thib ob ntawm lub phaj hlau thiab ua tiav kev tsim ntawm "C"; Thaum kawg, qhov qis dua ntawm "C" hom raj dawb paug yog khoov ib zaug kom paub txog "O" tsim. Lub hauv paus ntsiab lus ntawm txhua kauj ruam stamping yog peb-taw tes khoov.

Lub sijhawm tshaj tawm: Cuaj hlis-30-2022