DAmashishini e-omestic petroleum, iikhemikhali kunye nezinye izixhobo zamandla afuna inani elikhulu lentsimbi enobushushu obuphantsi ukuyila nokuvelisa izixhobo ezahlukeneyo zokuvelisa nezokugcina ezifana negesi yepetroleum enyibilikisiweyo, i-ammonia engamanzi, ioksijini engamanzi kunye ne-nitrogen engamanzi.

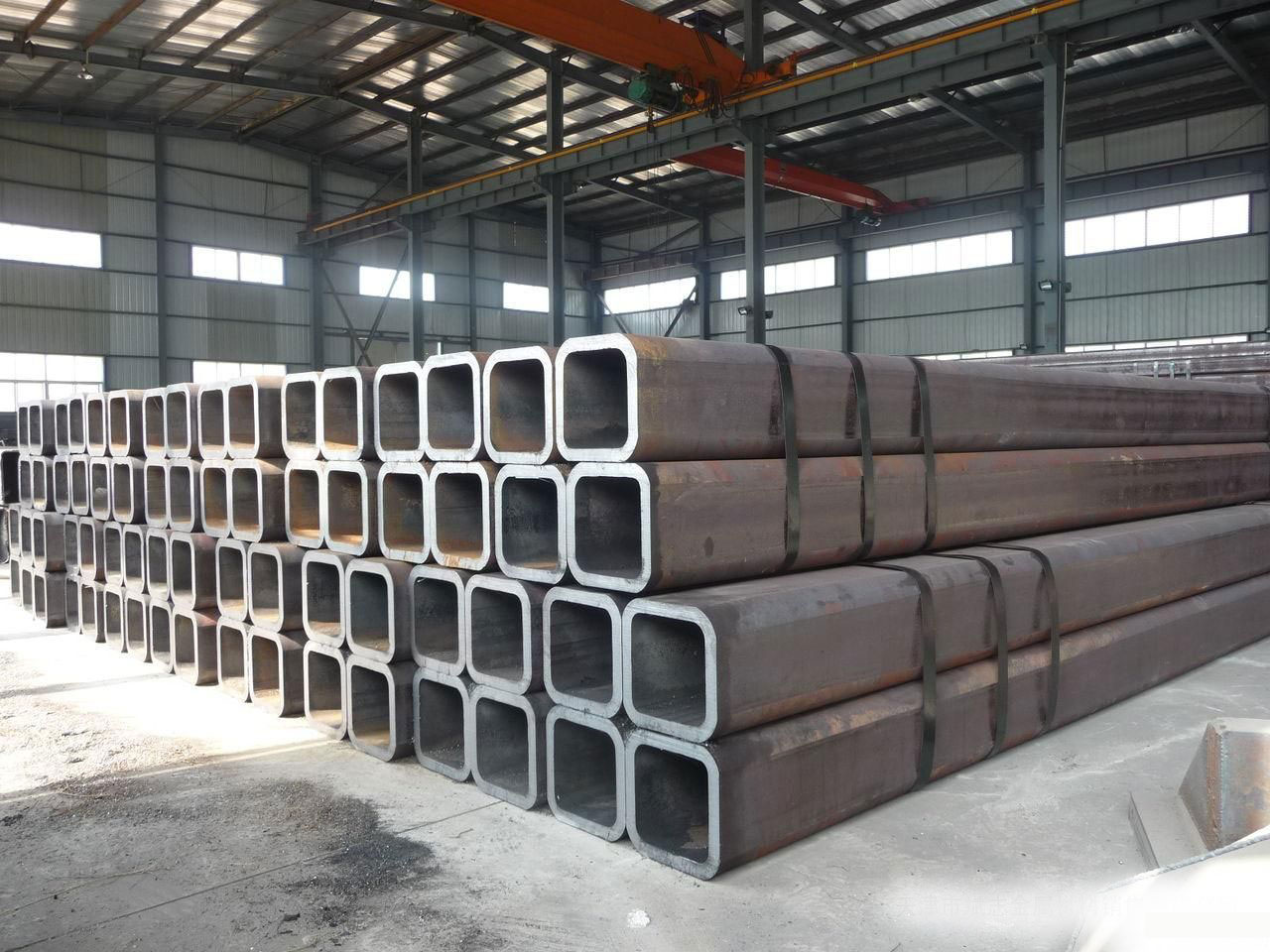

NgokweSicwangciso seMinyaka emihlanu se-12 saseTshayina, uphuhliso lwamandla e-petrochemical luza kuphuculwa kwaye uphuhliso lwezixhobo zeoyile negesi luza kukhawuleziswa kwiminyaka emihlanu ezayo. Oku kuza kubonelela ngethuba lemarike ebanzi kunye nophuhliso kwishishini lokuvelisa izixhobo zokugcina amandla phantsi kweemeko zenkonzo yobushushu obuphantsi, kwaye kuya kukhuthaza uphuhliso lweItyhubhu yoxande enganyangekiyo kubushushu obuphantsi be-Q355Dizixhobo. Njengoko iipayipi ezinobushushu obuphantsi zifuna ukuba iimveliso zingabi namandla aphezulu kuphela kodwa zibe nokuqina kobushushu obuphezulu nobuphantsi, iipayipi ezinobushushu obuphantsi zifuna ubunyulu obuphezulu bentsimbi, kwaye ngomlinganiselo weringi yobushushu, ubunyulu bentsimbi buphezulu. Q355Eityhubhu yesikwere yobushushu obuphantsi kakhuluiphuhlisiwe kwaye iyilwe. Intsimbi ye-billet ingasetyenziswa ngokuthe ngqo njengombhobho wentsimbi ongenamthungo wokwakha uthutho. Inkqubo yokuvelisa ibandakanya la manqaku mathathu alandelayo:

(1)Ukunyibilikisa isithando somlilo se-arc: intsimbi elahliweyo kunye nentsimbi yehagu zisetyenziswa njengeiimpahla ezingekasilwa, phakathi kwazo intsimbi elahliweyo ingama-60-40% kunye nentsimbi yehagu ingama-30-40%. Sisebenzisa iingenelo ze-alkalinity ephezulu, ubushushu obuphantsi kunye ne-iron oxide ephezulu yesithando sombane se-arc sombane esikumgangatho ophezulu, ukuxutywa ngamandla kwe-oxygen decarburization yi-bundle oxygen gun eludongeni lwesithando, kunye nokunyibilikisa amanzi okuqala okwenza intsimbi nge-impedance ephezulu kunye nesithando sombane se-arc sombane esikumgangatho ophezulu, izinto ezinobungozi i-phosphorus, i-hydrogen, i-nitrogen kunye ne-non-metallic inclusions kwintsimbi enyibilikisiweyo zinokususwa ngokufanelekileyo. I-End point carbon yentsimbi enyibilikisiweyo kwisithando sombane se-arc sombane < 0.02%, i-phosphorus < 0.002%; Ukususwa kwe-oxidation enzulu yentsimbi enyibilikisiweyo kwenziwa kwinkqubo yokucofa isithando sombane, kwaye ibhola ye-A1 kunye ne-carbasil zongezwa ukwenza i-deoxidation ngaphambi kokususwa kwe-oxidation.

Umxholo we-aluminiyam kwintsimbi enyibilikisiweyo ulawulwa kwi-0.09 ~ 1.4%, ukuze izinto ezifakwe kwi-Al203 ezenziwe kwintsimbi enyibilikisiweyo yokuqala zibe nexesha elaneleyo lokudada, ngelixa umxholo we-aluminiyam wentsimbi ye-billet tube emva kokucoca i-LF, unyango lwe-vacuum lwe-VD kunye nokuphoswa okuqhubekayo kufikelela kwi-0.020 ~ 0.040%, nto leyo ethintela ukongezwa kwe-Al203 eyenziwe yi-oxidation ye-aluminiyam kwinkqubo yokucoca i-LF. Ipleyiti ye-nickel ebalelwa kwi-25 ~ 30% ye-alloy iyonke yongezwa kwi-ladle ukuze i-alloying; Kwimeko apho umxholo we-carbon ungaphezulu kwe-0.02%, umxholo we-carbon wentsimbi yobushushu obuphantsi kakhulu awunakwanelisa imfuno ye-0.05 ~ 0.08%. Nangona kunjalo, ukuze kuncitshiswe i-oxidation yentsimbi enyibilikisiweyo, kuyimfuneko ukulawula amandla okuvuthela i-oxygen ye-oksijini yompu we-oksijini wodonga lwe-furnace ukulawula umxholo we-carbon wentsimbi enyibilikisiweyo ngaphantsi kwe-0.02%; Xa umxholo we-phosphorus ulingana ne-0.002%, umxholo we-phosphorus kwimveliso uya kufikelela ngaphezulu kwe-0.006%, nto leyo eya kunyusa umxholo we-phosphorus kwi-element eyingozi kwaye ichaphazele ukuqina kwentsimbi kubushushu obuphantsi ngenxa yokunyibilikiswa kwe-phosphorus equlethe i-slag evela kwi-electric furnace tapping kunye nokongezwa kwe-ferroalloy ngexesha lokucoca i-LF. Ubushushu bokuchukumisa be-electric arc furnace yi-1650 ~ 1670 ℃, kwaye i-eccentric bottom tapping (EBT) isetyenziselwa ukuthintela i-oxide slag ukuba ingangeni kwi-LF refined furnace.

(2)Emva kokucoca i-LF, i-wire feeder yondla i-0.20 ~ 0.25kg/t i-CA wire yentsimbi ecocekileyo ukuze isuse ukungcola kwaye yenze ukuba izinto ezifakwe kwintsimbi enyibilikisiweyo zibe yi-spherical. Emva konyango lwe-Ca, intsimbi enyibilikisiweyo ivuthelwa nge-argon ezantsi kweladle ngaphezulu kwemizuzu eli-18. Amandla okuvuthelwa kwe-argon angenza intsimbi enyibilikisiweyo ingaveli, ukuze izinto ezifakwe kwi-spherical kwintsimbi enyibilikisiweyo zibe nexesha elaneleyo lokudada, kuphuculwe ubunyulu bentsimbi, kwaye kuncitshiswe impembelelo yezinto ezifakwe kwi-spherical kwi-impact strongness ephantsi kobushushu. Ubungakanani bokutya be-CA wire ecocekileyo bungaphantsi kwe-0.20kg/t yentsimbi, izinto ezifakiweyo azinakususwa ngokupheleleyo, kwaye ubungakanani bokutya be-Ca wire bungaphezulu kwe-0.25kg/t yentsimbi, nto leyo enyusa iindleko ngokubanzi. Ukongeza, xa ubungakanani bokutya bomgca we-Ca bukhulu, intsimbi enyibilikisiweyo iyabila ngamandla, kwaye ukuguquguquka kwenqanaba lentsimbi enyibilikisiweyo kubangela ukuba intsimbi enyibilikisiweyo ifunxwe kwaye kwenzeka i-oxidation yesibini.

(3)Unyango lwe-vacuum ye-VD: thumela intsimbi enyibilikisiweyo ecociweyo kwisikhululo se-VD ukuze inyangwe nge-vacuum, gcina i-vacuum ingaphantsi kwe-65pa kangangemizuzu engaphezu kwama-20 ide i-slag iyeke ukugqwala, vula isigqubuthelo se-vacuum, uze uvuthele i-argon ezantsi kweladle ukuze ivuthe nge-static yentsimbi enyibilikisiweyo.

Ixesha lokuthumela: Sep-02-2022